Premium Welded Gabions for Strong and Lasting Structures

Premium Welded Gabions for Strong and Lasting Structures

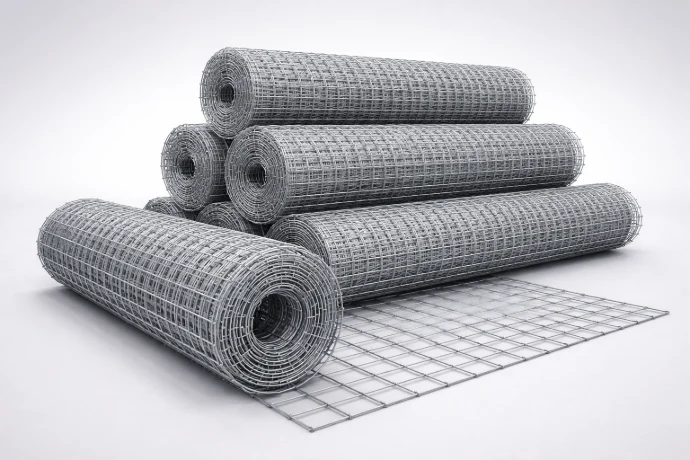

Welded Wire Mesh

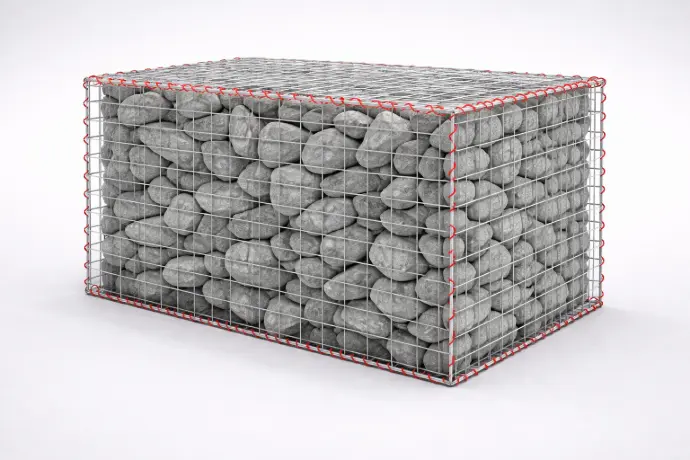

A welded mesh gabion, a rigid, box shaped structure is made of steel wires that are welded at all corners where longitudinal (horizontal) and transverse (vertical) wires intersect. This is a uniform grid welding process that produces stable openings of high precision. The weld panels are put together into containers and packed with stones or other objects to be used as structure or decorations. Welded mesh gabions are comparatively rigid unlike the much more flexible double-twisted mesh gabions, and still create permeable monolithic structures (e.g., retaining walls, channel linings, revetments) when built and filled.

Key Components of a Welded Mesh Gabion

Panels

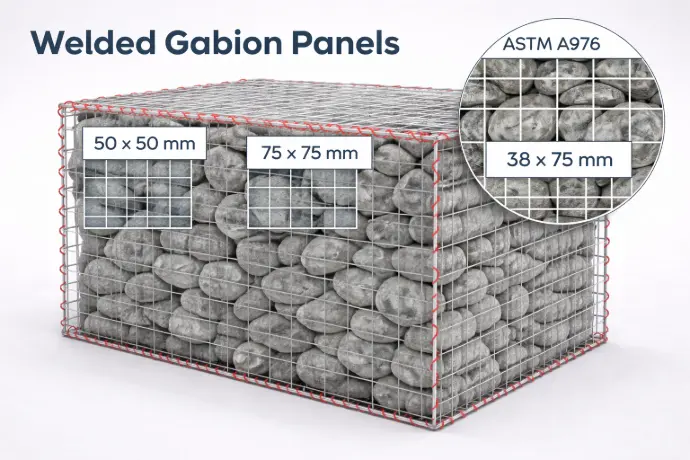

Panels consist of a welded mesh sheet that has a flat prefabricated sheet that is used in creating the face, base, back, and end wall of the gabion.

Function: They offer primary structural integrity, shape retention and containment of the stone fill.

Standards: BS EN 10223-8: Panels that are produced with accurate mesh apertures including 50x 50 mm or 75x 75 mm.

ASTM A974: Panels either in standard square (i.e. 75x75 mm), or in a rectangular (38x75 mm) mesh.

Lid

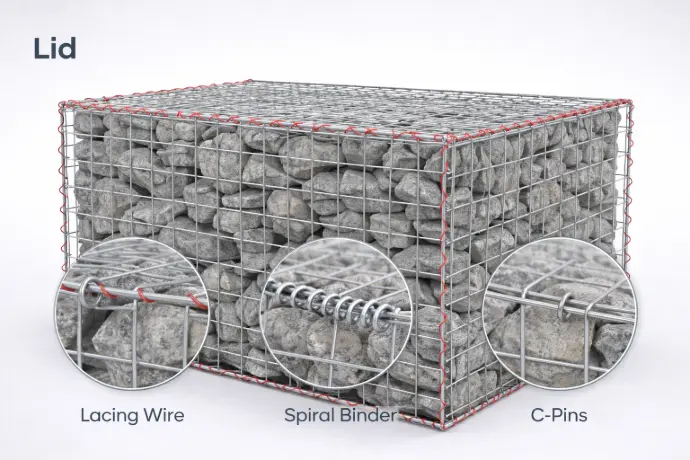

The lid will be a removable welded mesh panel that will be laid on the top of the gabion unit upon filling.

Function: It makes sure that the fill material is safely confined, able to be inspected in the future as well as adjusted or maintained.

Assembly: The closure is to be firmly and structurally stable, with lacing wire, spiral binders, or C-pins.

Diaphragm

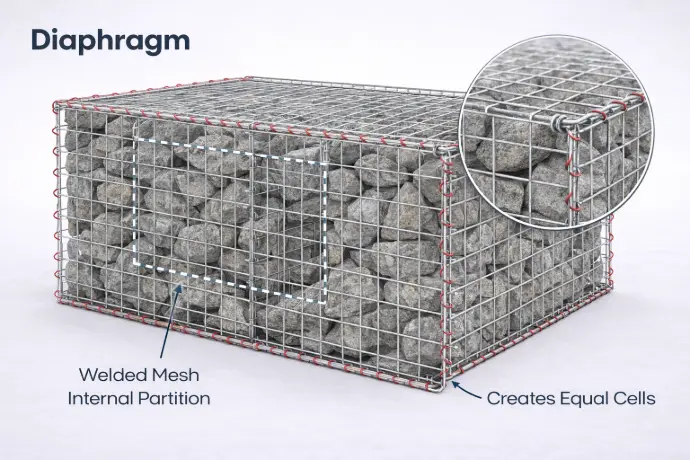

A diaphragm is a welded mesh internal partition attached to the gabion in order to subdivide it into equal cells.

Function: It reduces outward deformation (bulging), increases the load distribution, and the overall structural performance.

Spacing: The spacing is usually at 1-meter distance, but varies depending on the design specifications or project needs.

Lacing Wire

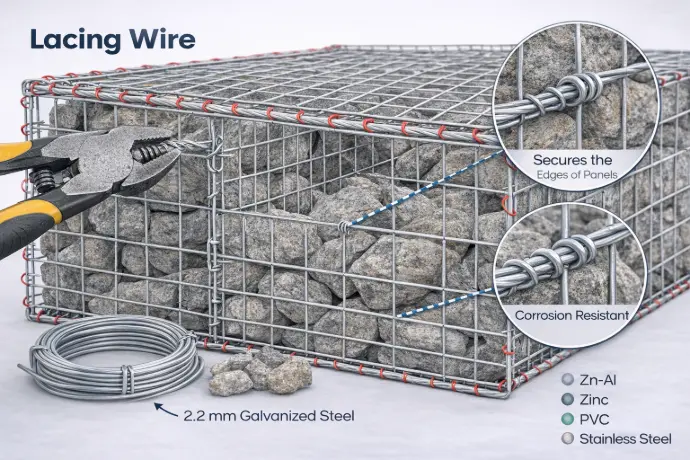

Lacing wire is a steel wire that has been coated against corrosion and is normally 2.2 mm or more in diameter and has a purpose of assembling gabion panels in the field.

Function: It attaches edges of panels, lids and diaphragms to obtain a safe and uninterrupted structural bond.

Coating: Provided with the same protective coating as the gabion system (e.g., zinc, Zn-Al, PVC or stainless steel).

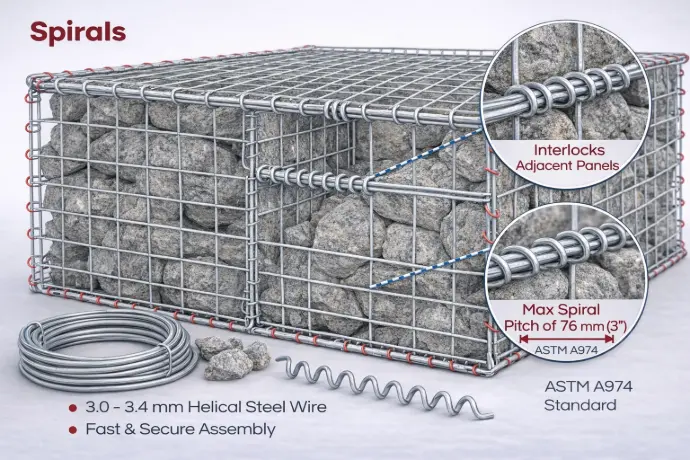

Spirals

- Spirals are binders made of helical steel wire, 3.0-3.4 mm in diameter, to facilitate the fast connection of panels.

- Function: They are used to interlock with adjacent edges of panels, and offer rapid reliable assembly with even load distribution.

- Standard: To guarantee tightness and secure engagement, ASTM A974 recommends a maximum spiral pitch of 3 in (76 mm).

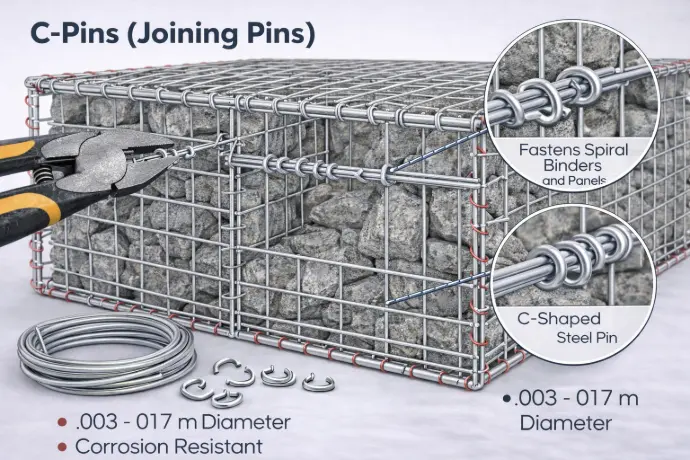

C-Pins (Joining Pins)

- C-pins are C-shaped steel joining rings or pins (0.003 m to 0.017 mm in diameter).

- Function: They are used to fix spiral binders or the edges of panels, which increases stability in connection.

- Recommendation: BS EN 10223-8 suggests that they should be used together with spirals in assembling welded mesh gabion panels.

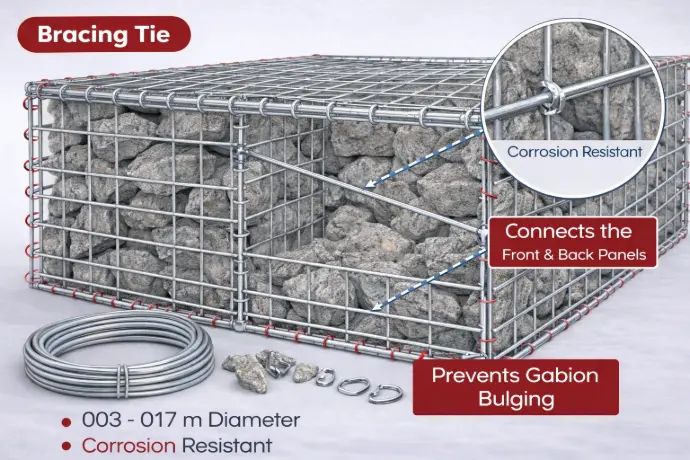

Bracing Tie

- A bracing tie is an internal diagonal wire or rod between parallel gabion panels.

- Function: It fixes the unit by bonding the front and back panel, which does not deform under the rock load.

- Content: Made of the same corrosion-resistant coating as of the

main gabion mesh (e.g., zinc, Zn-Al, PVC).

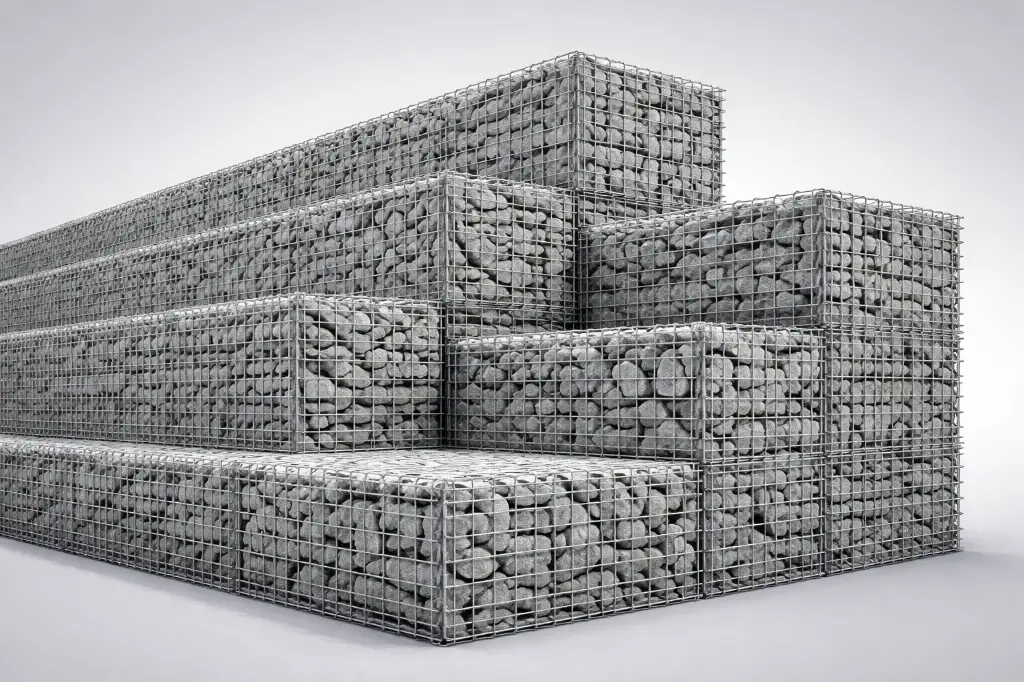

Build strong and elegant structures with Welded Gabions

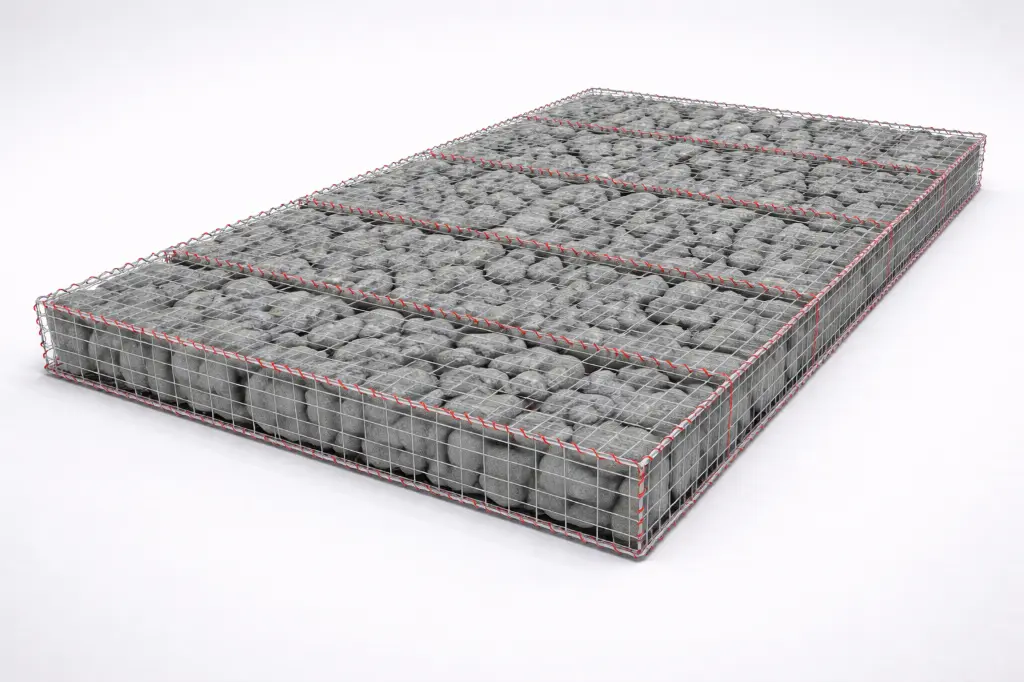

Types of Welded Mesh Gabion Products

Specifications of Welded Wire Mesh Gabion

Specifications (ASTM A974 & BS EN 10223-8)

The welded mesh gabions are produced according to internationally accepted standards, which define the mesh size, wire gauge, coating type, and performance requirements. The key specifications are summarized in the tables below.

ASTM A974:

| Typical ASTM Gabion Specification | Coating | Mesh size | Wire diameter | Shear strength | Lacing |

|---|---|---|---|---|---|

| Gabion Box | Galvanized | 76 × 76 | 3.05 mm | Min. 70% of wire tensile strength | 2.2 mm (galvanized) |

| Gabion Box | PVC coated | 76 × 76 | 2.7 mm | 2.2 mm (PVC coated) | |

| Gabion Mattress | Galvanized / PVC | 38 × 76 | 2.2 mm | 2.2 mm (same as mesh) |

BS EN 10223-8

| Typical ASTM Gabion Specification | Coating | Mesh size | Wire diameter | Shear strength | Lacing |

|---|---|---|---|---|---|

| Gabion Box | Hot-dip galvanized, Zn-5%Al (Galfan), PVC-coated | 100 × 100 | 5 mm | Min. 75% of wire breaking load |

3.76 mm (spiral) 3 mm (C pins) 2.2 mm lacing wire |

| Gabion Box | 100 × 50 | 4 mm | |||

| Gabion Box | 75 × 75 | 3 mm | |||

| Gabion Mattress | 75 × 50 | 2.7 mm | |||

| Gabion Mattress | 50 × 50 | 2.4 mm |

Coating Options

| Coating Type | Standard | Composition | Corrosion Resistance |

Application |

|---|---|---|---|---|

| Galvanized Steel | ASTM A641 (Class 3) | Zinc-coated wire | Moderate | Standard environments with low to moderate moisture exposure. |

| Zn-5%Al (Galfan) | ASTM A856 (Class 3) | Zinc–Aluminum alloy (95% Zn, 5% Al) | High | Suitable for coastal and high-moisture environments. |

| PVC Coated | ASTM A974 | Galvanized / Zn-5%Al wire + PVC layer (0.5 mm) | Very High | Highly corrosive areas, such as marine and industrial applications. |

| Aluminized Steel | ASTM A809 | Aluminum-coated steel wire | Very High | Used in extreme weather conditions for long-term durability. |

Contact Us

Enquire Now — Strong Welded Gabion Systems for Retaining, Protection & Landscaping

Ready to build with welded gabions? Enquire now for design support, technical guidance, and pricing.

Downloads

Contact Hitech Gabion for Expert Advice on Welded Gabions

Interested in our gabion planters? Contact us today for a quote or to discuss your specific needs. Our team is ready to help you find the perfect solution for your space.