Woven Wire Mesh for Durable and Versatile Solutions

Woven Wire Mesh for Durable and Versatile Solutions

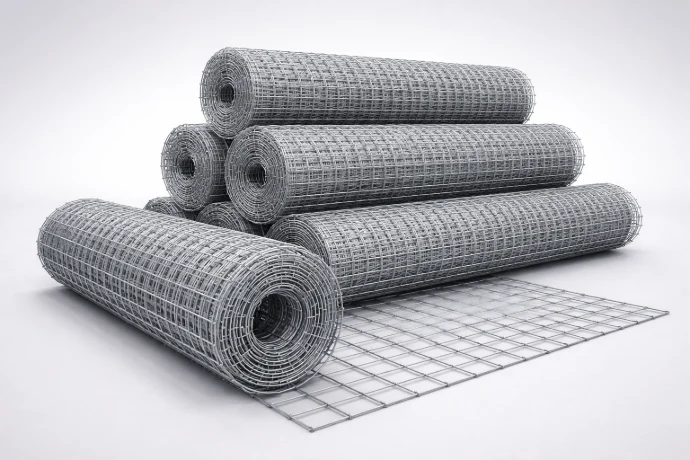

Woven Wire Mesh

Woven Wire Mesh is an interlocking mesh design of two connecting wires that are twisted together 2.5 times (3 half-turns) creating a strong mesh pattern that will not ravel. The process is an extremely flexible, strong, and resistant manufacturing technique that is resistant to tearing apart even during cutting. The mesh is made in panels (base, sides, lids) and fitted together into gabion formations.

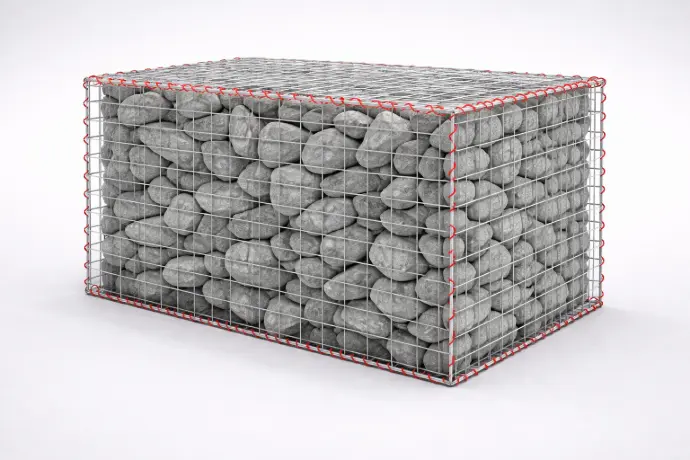

Gabion Box Components (Durable and Versatile Gabion Box Solutions)

Base Panel

Primary structural mesh panel that forms the base of the gabion unit and carries the full stone load.

Lid Panel

Removable top mesh panel used to close the gabion after filling and to lock the stone in position.

Diaphragms

Internal mesh partitions that divide the basket into cells, improving stability and controlling stone movement.

Selvedge Wire

Thicker border wire providing edge strength, e.g. 3.4 mm selvedge combined with 2.7 mm mesh wire.

Lacing Wire

2.2 mm wire used to lace and assemble panels together, ensuring tight connections along all edges.

Fasteners

C-rings or clips that mechanically connect adjacent panels and speed up on-site installation.

Bracing Ties

Diagonal internal wires that prevent bulging of the mesh faces during and after stone filling.

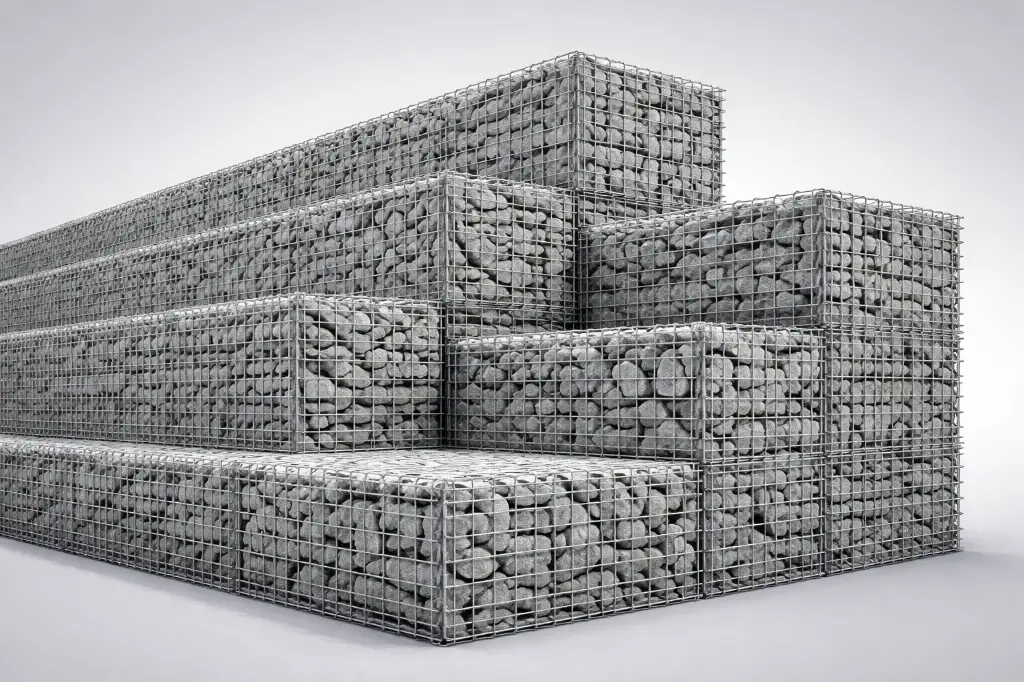

Sack Gabions

Cylindrical gabion units designed for rapid filling and placement, ideal for emergency works and river training.

Type of Gabion Products

Secure your projects with durable Woven Wire Mesh

Secure your projects with durable Woven Wire Mesh

Gabion woven Wire Mesh Technical Specifications

Gabion woven Wire Mesh Technical Specifications

Specifications (ASTM 975 & BS EN 10223-3:2013)

Welded mesh gabions are manufactured in accordance with international standards, which define mesh type, wire diameter, selvedge wire, and structural performance. The key specifications for ASTM 975 and BS EN 10223-3:2013 are summarized below.

ASTM 975

| Characteristic | Gabion (Metallic) | Gabion (PVC) | Gabion Mattress (Metallic / PVC) |

|---|---|---|---|

| Coating | Metallic | PVC | Metallic / PVC |

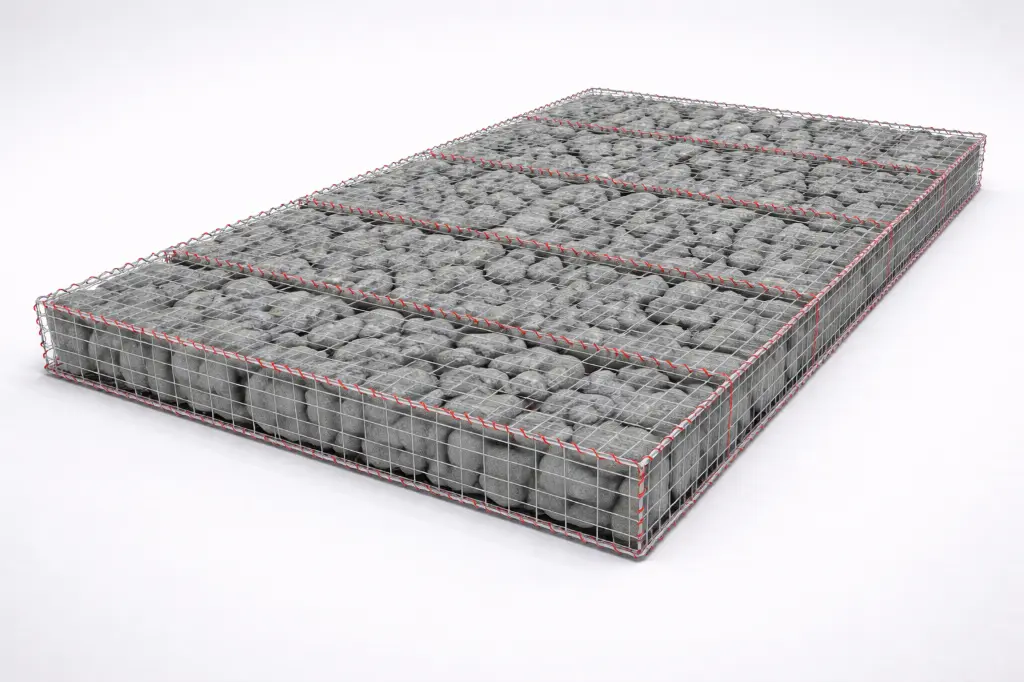

| Mesh type | 80 × 100 | 80 × 100 | 60 × 80 |

| Mesh opening | 83 × 114 | 83 × 114 | 64 × 83 |

| Wire diameter (mm) | 3.05 | 2.7 | 2.2 |

| Selvedge wire (mm) | 3.8 | 3.4 | 2.7 |

| Lacing wire (mm) | 2.2 | 2.2 | 2.2 |

| Fasteners | 3 mm | 3 mm | 3 mm |

| Stiffener | 2.2 / 3.8 mm | 2.2 / 3.8 mm | 2.2 / 3.8 mm |

| Coating system |

Style 1 (Zinc) Style 2 (Zn-5% AlMM) Style 4 (Aluminum) |

Style 3 (PVC over Zinc) | Style 1 – Style 4 |

BS EN 10223-3:2013

| Mesh Size (mm) | Wire Diameter (mm) | Type of Product |

|---|---|---|

| 50 × 70 | 2.0 | Mesh in roll |

| 60 × 80 | 2.0 | Mesh in roll / Mattresses |

| 2.2 | Mesh in roll | |

| 2.4 | Mesh in roll | |

| 2.7 | Mesh in roll: Gabions | |

| 80 × 100 | 2.2 | Retaining structure |

| 2.4 | Mesh in roll | |

| 2.7 | Retaining structure: Gabions | |

| 3.0 | Mesh in roll / Gabions | |

| 3.4 | Mesh in roll | |

| 3.9 | Mesh in roll | |

| 100 × 120 | 2.7 | Mesh in roll |

| 3.0 | Mesh in roll |

Coating

Coatings prolong lifetime of gabions, which include corrosion resistance, UV-resistance as well as resistance to harsh environment. Standards are used to establish the type of coating, resistance to corrosion, tensile and permanence with environment

ASTM 975

The ASTM standard emphasizes parameters like coating mass and tensile strength for gabion boxes and mattresses

| Coating | Style | Standard |

|---|---|---|

| Galvanized | Style 1 | ASTM 641 Class 3 |

| Zn–5% Al | Style 2 | ASTM A856 Class 3 |

| PVC | Style 3 | ASTM 975 (0.5 mm thickness) |

| Al | Style 4 | ASTM A809 |

Contact Us

Enquire Now — Durable Woven Gabion Mesh Solutions for Slopes, Channels & Walls

Need reliable woven wire mesh gabions? Contact our engineering team today.

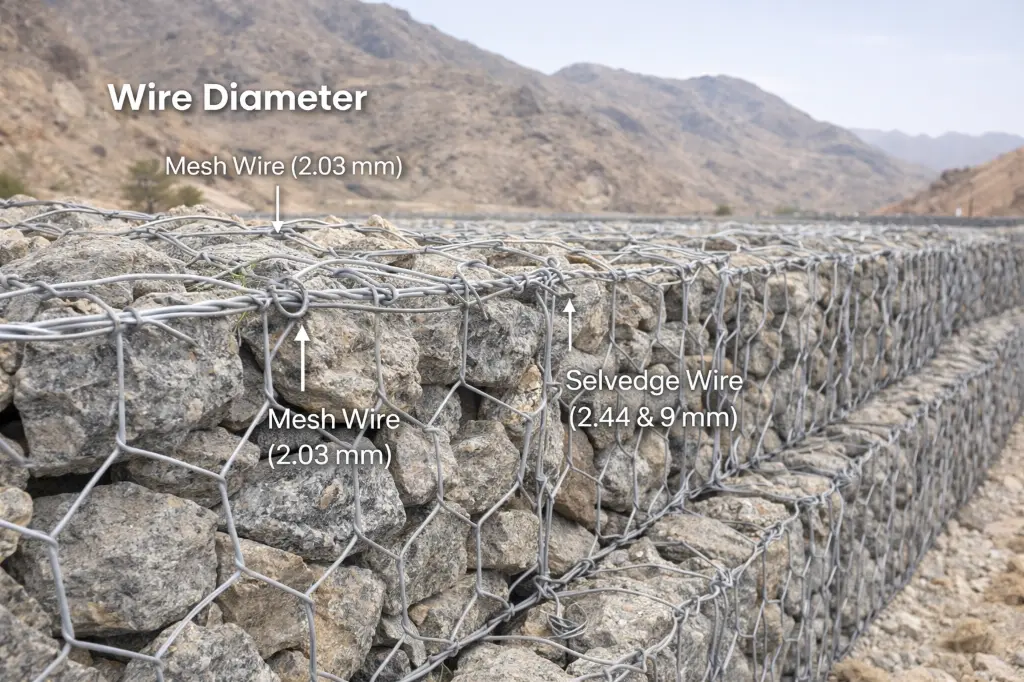

Diameter of Wire to Selvedge Wire Diameter

Wire Diameter

Mesh wires are either 2.03.9 mm, and selvedge wires are 2.44.9 mm to increase the strength of the edge. Selvedge wires enhance rigidity, do not deform when filled and have enhanced durability with environmental loads of long term.

- Mesh Wire (2.03.9 mm): Preponderating body of the gabion.

- Selvedge Wire (2.44.9 mm): Strengthens sides.

- Greater Stability: Decreases distortion and increases service life.

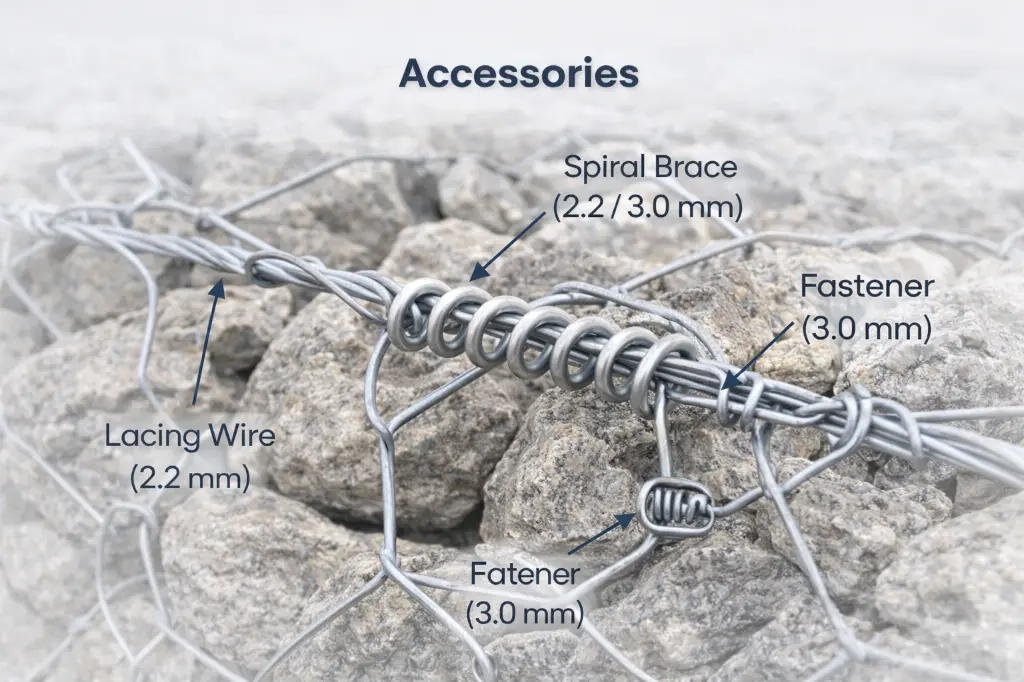

Accessories

Gabion accessories are the necessity of structural stability and correct assembly, as well as long-term performance. Mesh panels are laced with wires (2.2 mm) and equipped with 3.0 mm fasteners to allow the faster installation process. Braces (2.2 mm or 3.0 mm) ensure form and stop external protrusion during pressure. The combination provides general strength and efficiency in installation.

- Lacing Wires (2.2 mm): To tie and fix panels.

- Fasteners (3.0 mm): allow more rapid mechanical assembly.

- Bracing Ties (2.2 / 3.0 mm): Avoid deformation and enhance stability.

BS EN Standard

The BS EN standard presents new requirements of composing complex coating and durability to guarantee that the gabion mesh will work in hard conditions. It incorporates corrosion test, chemical exposure resistance and measurement of material quality to increase the structural life span in the coastal, industrial and high moisture applications.

- Salt Spray Resistance: Guarantees extended corrosion protection.

- SO 2 Exposure: Evaluates the test resistance under contaminated air.

- Stainless Steel Requirements: Specifics corrosion-resistant grades that are of high strength.

- Poly amide (PA) Coating: Provides UV and abrasion protection

Applications of Woven Wire Mesh

Industrial and Commercial

Construction and Reinforcement

Architectural and Decorative

Contact Us for Bulk Orders of Woven Wire Mesh

Reach out today to discuss your woven wire mesh needs. We offer competitive pricing and exceptional customer service for bulk and custom orders.