Time is money in the large scale construction and landscaping projects. The Saudi Arabian contractors engaged in villas, highways, slope protection, and flood-control structures are continuously seeking how to complete the projects within the quickest time possible and without compromising on the quality. The use of pre-filled gabion baskets is one of the most rapidly developing solutions: the cages have been filled with the stone and installed on-site ready-made cages.

In contrast to the traditional gabions where one has to fill the gabions on-site which is also a time-consuming and labour intensive process, pre-assembled gabion baskets are already assembled and filled with content and wired which reduces construction and labour costs. However, are they suitable for all projects? Let’s explore.

What Are Pre-Filled Gabion Baskets?

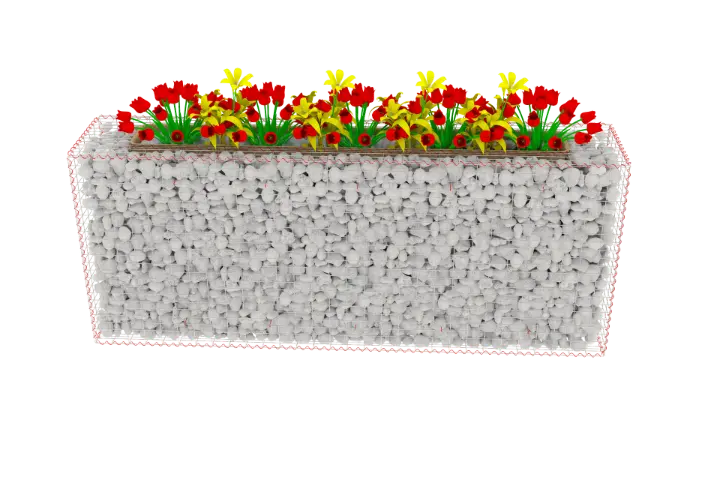

A pre-filled gabion basket is a cage composed of galvanized, PVC-coated, stainless steel or Galfan mesh which has been factory packed with some combination of preselected stones. These units are pressed, strained and transported to the location in ready to place units.

- Conventional Gabions: This is delivered in empty form, but filled with stone on-site.

- Ready-Prepared Gabions: ready-made and not loaded.

This basic distinction can shorten weeks on a project schedule based on project size and magnitude.

The benefits of Pre-Filled Gabion Baskets

Time Savings

- On site stone filling is not required, just unload and fit.

- Of particular use in large infrastructure projects where several meters of wall are required in hundreds.

The perfect choice when the contractor is dealing with a limited timeframe (e.g. highway slope stabilization prior to rainy season).

Consistent Quality

- Baskets with stones to guarantee even placement, compaction and aligning of the stones.

- Reduced chances of bad workmanship, which may occur in case of on-site labor.

Reduced Labor Costs

- Skilled crews, equipment and oversight are usually needed during on-site filling.

- This requirement is minimized by pre-filled baskets, which lower contractor payroll

Durability & Strength

- In factory conditions, stones are compacted closely and thus settlement and voiding is minimized with time.

- Wire mesh is pre-stressed and is well fastened hence there is a low possibility of deformation.

Efficient in Remote or challenging Locations

- In the mountainous region, desert or coastal region of Saudi Arabia, it is not easy to transport loose stone and do some filling.

- Ready-made gabions are easy to logistically work with, as all that is needed is to position the modules using a crane or forklift.

Disadvantages of Pre-Filled Gabion Baskets.

- Increased initial expense: Preparation and transportation of heavier and bulkier units in the factory is costly.

- Transport Problems: Pre-filled units weigh more and consume more space, which raises the cost of shipping over empty flat-packed gabions.

- Reduced On-Site Flexibility: Once units have been shipped, contractors are unable to adjust the type, size or color of the stone.

- Equipment Requirement: Construction normally needs cranes or forklifts among other equipment.

Pre-Filled vs Traditional Gabions – Quick Comparison

A concise comparison between pre-filled and traditional gabion systems used in retaining walls, slope protection, and drainage applications across Saudi Arabia.

| Factor | Pre-Filled Gabion Baskets | Traditional Gabion Baskets |

|---|---|---|

| Installation Time | Very fast – just unload & place | Slower – on-site stone filling required |

| Labor Requirement | Minimal (crane/forklift only) | High (stone filling team needed) |

| Upfront Cost | Higher | Lower |

| Transport Efficiency | Bulky, more costly | Compact, cheaper to transport |

| Quality Control | Factory controlled | Depends on site labor |

Most appropriate applications in Saudi Arabia.

Gabion baskets that have been filled in advance are particularly useful in:

- Highway Embankments: Accelerating slope stabilization.

- Flood Defenses and Riverbanks: Issue on which prompt action is necessary prior to rains.

- Coastal Protection Walls: Rapidly and easily installed against storm surge and erosion.

- Urban Landscaping Projects: These are villas, parks or urban beautification projects where the contractors require an expedited polished look.

- Remote Projects: Mountainous or desert-based projects that are characterised by the scarcity and high cost of labour.

Hitech Gabion - Contractor Supplier Choices

Hitech Gabion is a reliable supplier of pre-filled gabion baskets to the contractors in Saudi Arabia. They offer long-lasting and economical methods of highways, flood-control projects, retaining walls and landscape projects. This emphasis on fast delivery, desert-hardy durability and tailor-made risks make Hitech provide that the contractors will save time and labor during installation.

Conclusion

Gabion baskets that are pre-filled are an intelligent time-saving solution to contractors in Saudi Arabia who are dealing with infrastructure as well as landscaping projects. Though they are associated with a high initial and transportation cost, their lower labor and construction time, as well as quality uniformity ensure that they are very cost-effective in the long term. When villa landscaping, beautifying an urban area, highways, or flood-control endeavors receive tight deadlines, pre-filled gabion baskets have the potential to redefine the way a contractor plans and constructs a building.

For villa landscaping, highways, urban beautification, and flood-control projects under tight deadlines, pre-filled gabion baskets from Hitech Gabion can redefine the way contractors plan and build.