Free Standing wall

Free Standing wall

Experience the growing trend of gabion walls as freestanding structures, gaining popularity in both commercial and residential environments. Suitable for a variety of functions, these walls can withstand wind and pedestrian loads, whether supported by their own weight or supplemented with internal steel supports. From a security screen to an architectural feature or noise barrier, gabion walls offer versatility and sustainability. With the right choice of aggregate and thoughtful incorporation of planting schemes, they prove to be an environmentally friendly alternative that seamlessly blends functionality with aesthetics.

Gabion Baskets

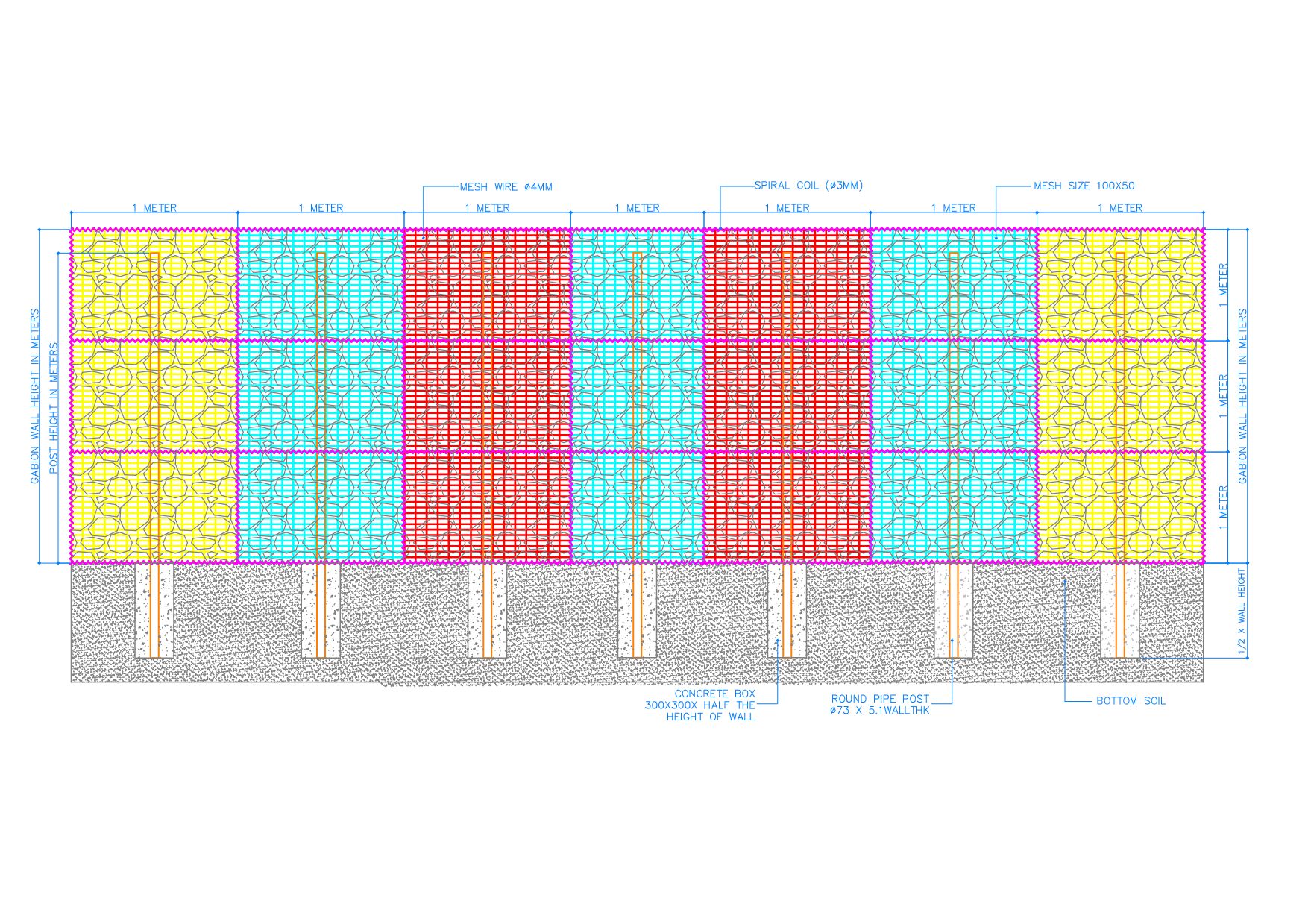

Hitech knows the diverse requirement of the industries these days. For this, Hitech offer gabion basket in two categories of meshes, welded wire mesh and double twisted hexagonal mesh. In For free standing gabion wall, we recommend using welded wire mesh for free standing gabion wall as welded mesh wire provides much better strength and resistant to shape change due to stress as adjacent meshes bear major loads. Welded wire mesh is fabricated from 4 mm carbon steel wire is used to create the mesh structure by welding at every junction with mesh opening of 100x 50 mm. Joining of these meshes depends on the design of wall however, spiral coil of 20mm diameter with 45 mm pitch is used to secure the meshes in place.

Design

There are multiple design options are available for free standing gabion wall.

Design A: To stabilize the wall and prevent any movement or bending, a central support post is employed. A schedule 40 circular pipe with an outer diameter of 73 mm and a wall thickness of 5.1 mm is inserted into a ground hole measuring 300x300, extending to half the height of the wall. Concrete is then poured into this hole to secure the pipe in place. Specific sections of the gabion boxes are trimmed to allow for stacking directly onto the pipe, creating a seamless interlocking of the basket and the pipe. To further secure the panels, supporting wires are used. This setup is suitable for free-standing gabion walls with a height of 4 meters or more. This configuration gives strength and resistant to bending as well as excellent for cladding purposes.

Design B: An alternative approach involves utilizing a square pipe affixed to a sturdy base plate, boasting a thickness of 10mm. The square pipe, customed to the required width, is securely welded onto the base plate, which is then anchored to the concrete floor below. To ensure stability, a robust 50x50 flat square metal clip spans the entire length of the post, firmly securing the front and back gabion welded mesh. Unlike traditional designs, the sides of the gabion basket are omitted in this setup, resulting in cost savings without compromising structural integrity. However, this design is best suited for intermediate heights of up to 3 meters, with a maximum width of 200mm. Not only does this configuration lend a pleasing aesthetic to your project, but it also serves as an excellent option for building cladding.

Design C: Another approach involves using U-shaped channels to provide external support for the gabion box. This design simplifies installation, requiring customers only to insert the gabion box between the channels. The channels are welded to a base plate with a maximum thickness of 10mm and anchored to the ground using bolts for added stability. This design is particularly suitable for gabion walls up to 3 meters high and 300mm wide, making it ideal for cladding and free-standing walls near buildings and pathways.

Shape Control

When comparing welded wire mesh and double twisted hexagonal mesh, although both have their own pros and cons. Double twisted mesh is better suited for application where we need flexibility without fracture. But for free standing wall, rigidity and strength is more important factor t be considered. Welded wire mesh provides better structural strength and durability than any mesh which is best suited for shape control and for aesthetic look to your project.

Customization

Hitech knows the diversity of the industrial need, for this we offer customization is design, dimensions and even in finish coating as well for success of our customer. Our technical team is always available to better assist you in your project, feel free to contact us. Although, we provide heavy galvanized coating as per ASTM 641 class 3. However, upon request we can provide customized coating and colors.