Reno Mattresses

Reno Mattresses

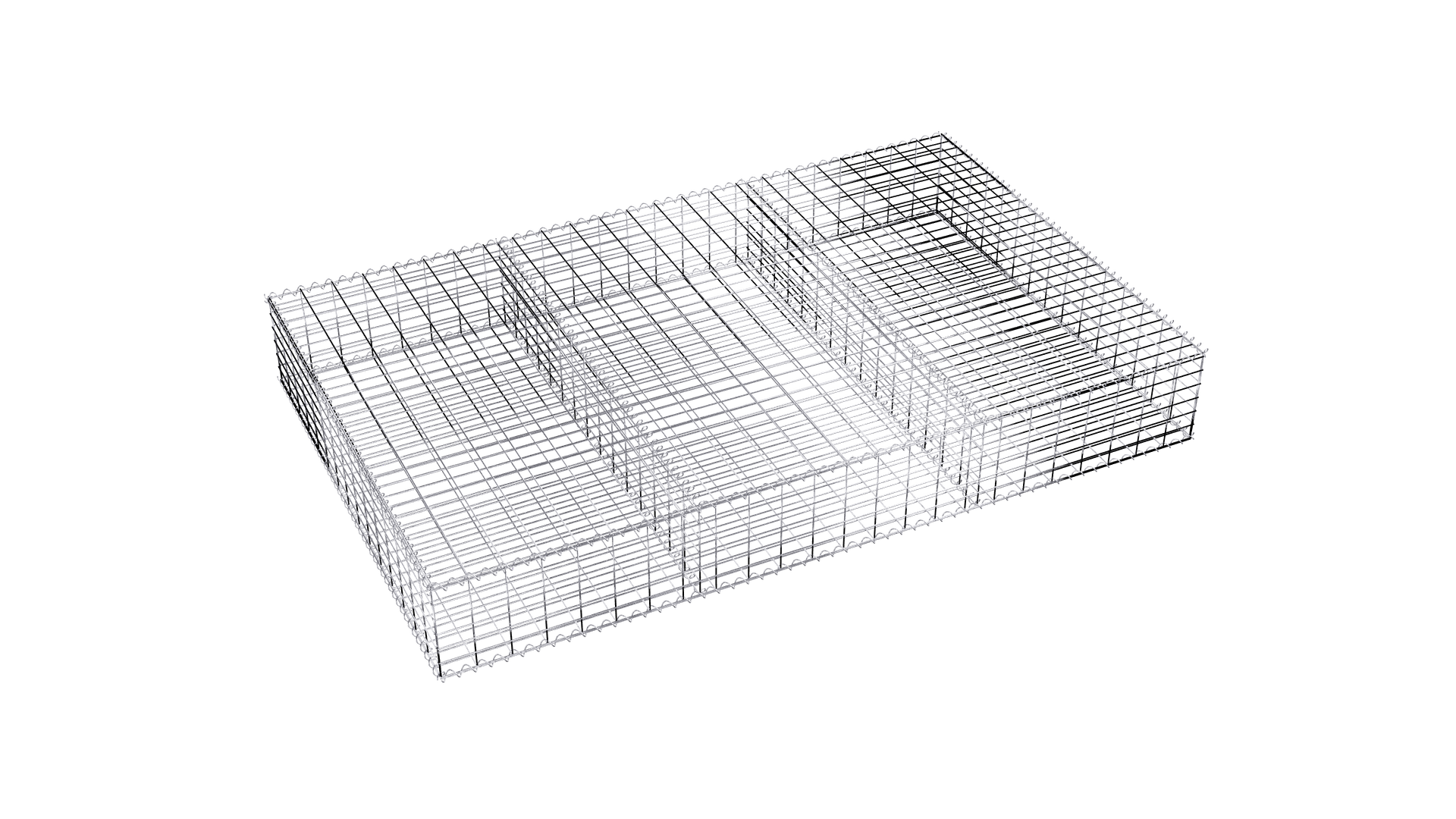

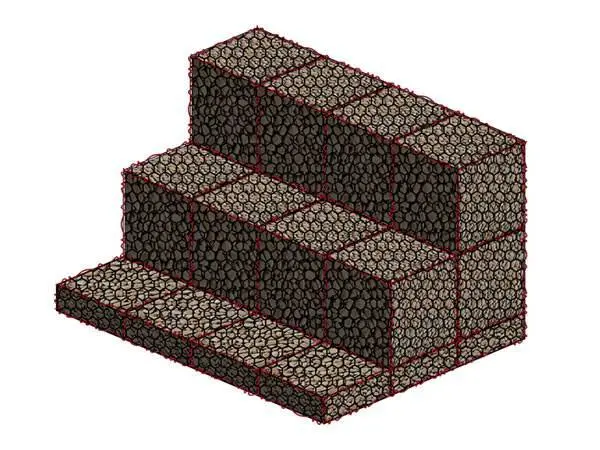

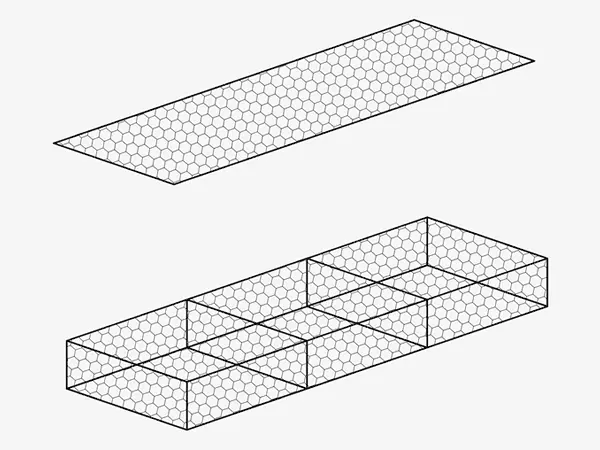

Reno mattresses are construction elements similar to gabion boxes but with longer length and shorter height. They come in rectangular shapes and are used for various applications, both large and small, in residential and commercial settings. Reno mattresses offer lower labor costs than gabions due to their flexibility and require less heavy equipment for installation. Crafted from steel wire, they provide strength and durability, making them essential for slope protection, erosion control, shoreline protection, and embankment stabilization

Double Twisted Wire

Reno mattresses are made from 3mm diameter double twisted wire with mesh opening of 100x80mm, offering both flexibility and durability for projects dealing with uneven terrains and bends. Manufactured according to ASTM A975-97 standards, they consist of twisted woven galvanized steel wire mesh. These mattresses are partitioned into three equal-sized compartments using diaphragms, ensuring uniform distribution of stone filling. This even distribution enhances structural integrity and fosters close ground contact, essential for effective stabilization.

Reno

Mattresses

|

Double

Twisted Wire

|

Material

|

Steel

Wire

|

Wire

Diameter

|

3mm

|

Mesh

opening

|

100x80mm

|

Lacing

|

2mm

steel wire

|

Lacing

pitch

|

50mm

|

Corrosion

Resistant

|

Yes

|

Assembly

Required

|

Yes

|

Finish

coating

|

Galvanized/

PVC coating

|

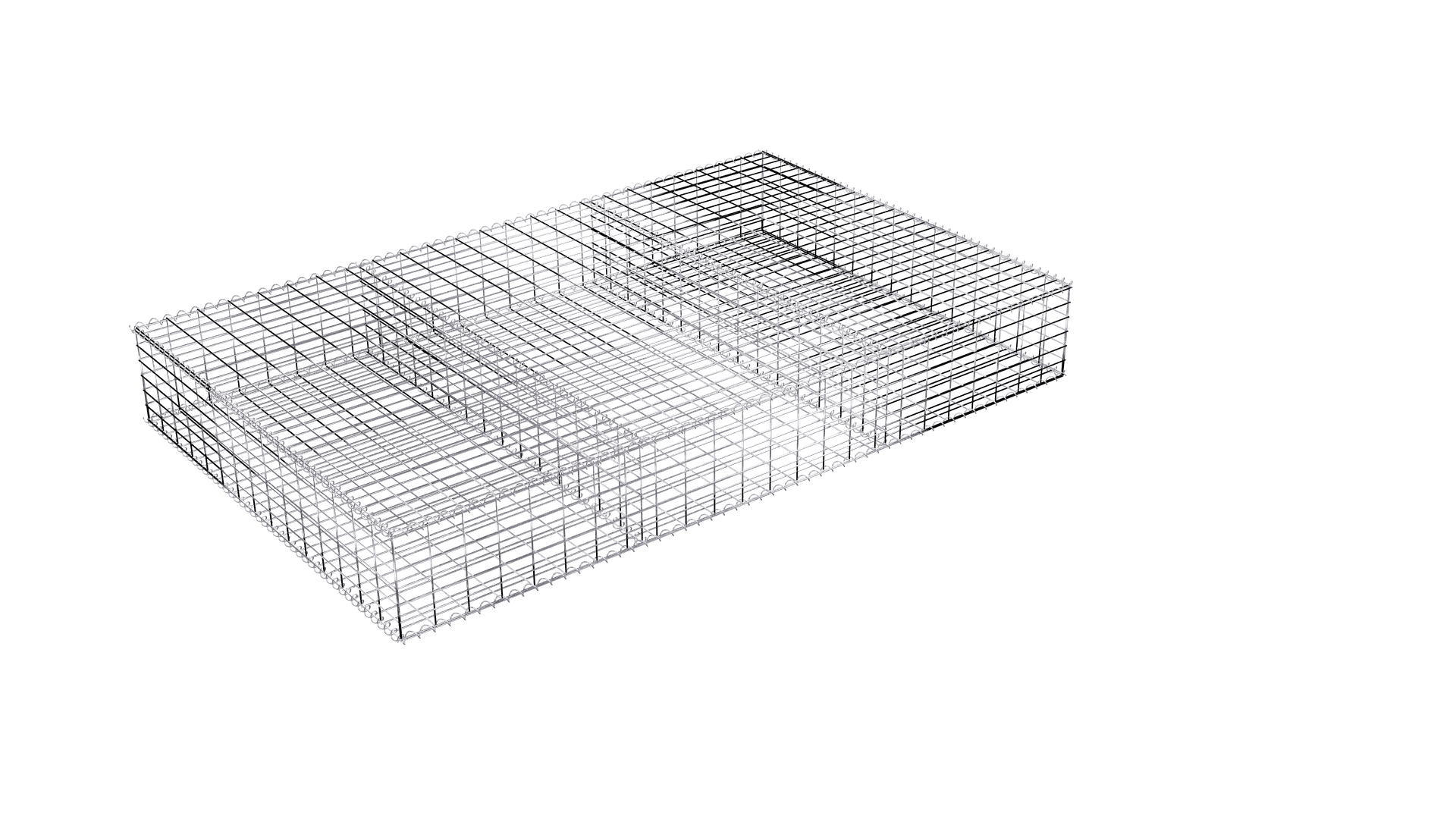

Welded Mesh wire

Welded Mesh reno mattresses are manufactured from carbon steel wire which boast exceptional mechanical properties, notably in weldability. They are composed of 4mm diameter wires intricately welded into a mesh configuration measuring 100x50 mm, resulting in an impressive loading capacity exceeding 1400 kg/m3. Unlike conventional woven wire constructions, these mattresses offer superior strength and longevity due to their smartly welded at every intersection. Welded mesh structure is added for partition of the mattresses into three same dimensioned portions this allows for even distribution of the stones in each compartment. For stability and cohesion, the mesh structures are interconnected using spiral coils with a 3mm diameter, featuring an internal diameter of 20mm and a pitch of 45mm. This combination of robust materials and precise engineering, welded Mesh Wire mattresses ideal for a diverse application requiring strength, durability, and load-bearing capacity.

Reno Mattresses

|

Welded Mesh wire

|

Material

|

Carbon steel wire

|

Wire Diameter

|

4mm

|

Mesh Opening

|

100x50

|

Mesh Loading capacity

|

1400 kg/m3

|

Lacing

|

Spiral coil of 3mm

|

Coil Pitch

|

45mm

|

Coil internal diameter

|

20mm

|

Corrosion Resistant

|

Yes

|

Assembly required

|

Yes

|

Finish Coating

|

Galvanized/ PVC

|

Variants

Hitech Gabion knows the diverse requirement of the industry for this, we offer 9 variants with 3 variants in length and 3 variants in height in addition to special variant of height up to 450mm. which would be available in request.

|

Article

Numbers

|

Length |

Width

|

Height |

|

GC110

|

2400mm

|

1500mm

|

200 mm

|

|

GC120

|

2400mm

|

1500mm

|

300mm

|

|

GC130

|

2400mm

|

1500mm

|

450mm

|

GC140

|

3600 mm

|

1500mm

|

200 mm

|

GC150

|

3600 mm

|

1500mm

|

300mm

|

GC160

|

3600 mm

|

1500mm

|

450mm

|

GC170

|

4500mm

|

1500mm

|

200 mm

|

GC180

|

4500mm

|

1500mm

|

300mm

|

GC190

|

4500mm

|

1500mm

|

450mm

|

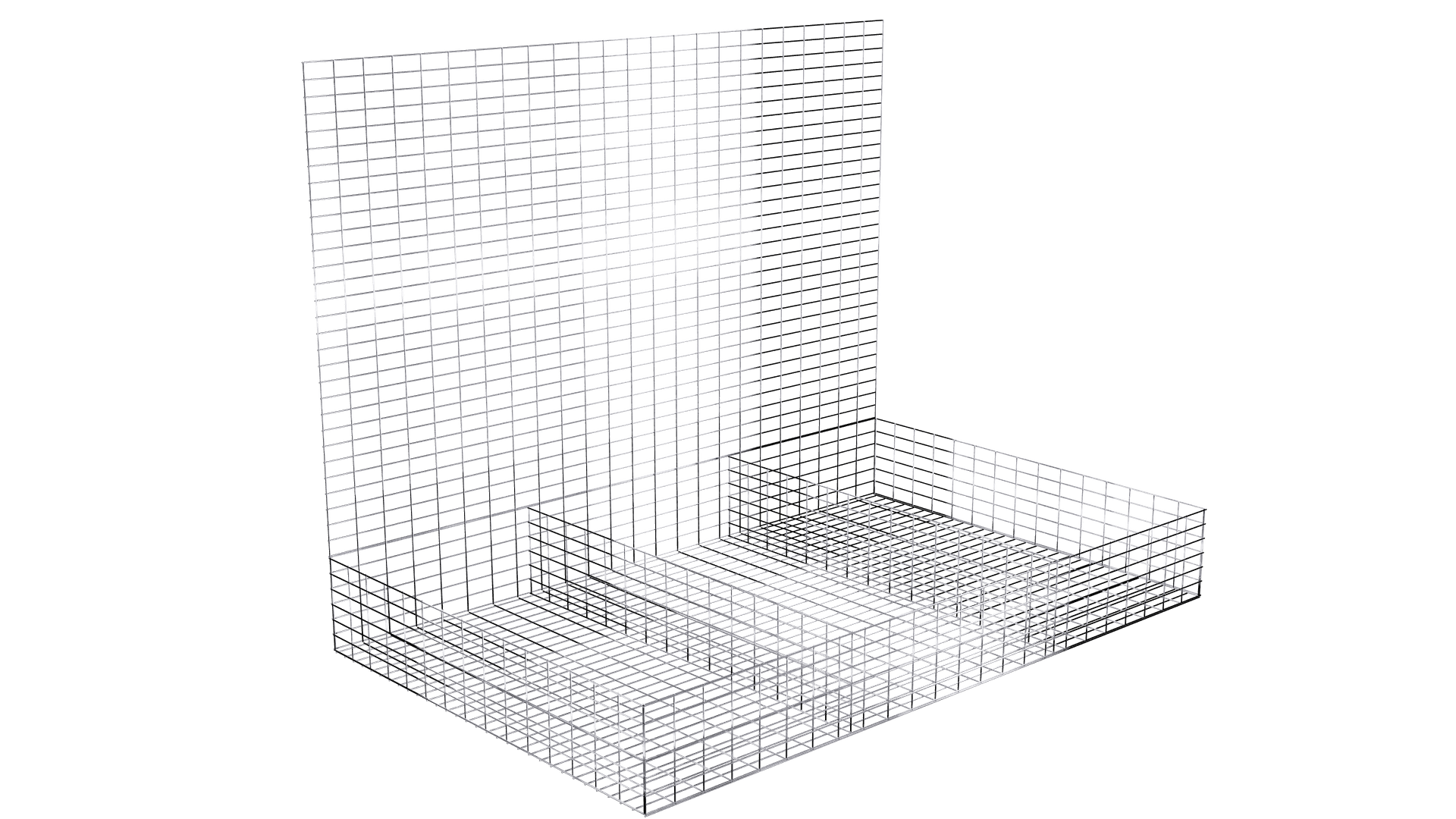

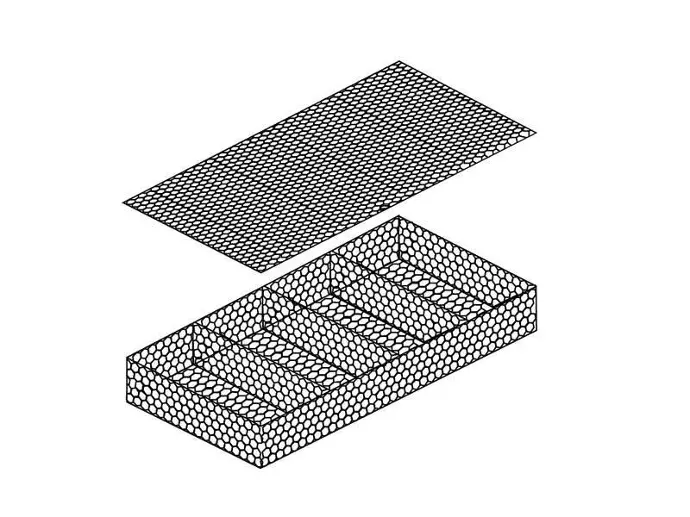

Delivery and Assembly

Reno mattresses are typically delivered in rectangular baskets with flat panels hinged together. During installation, diaphragms are temporarily positioned with the assistance of fasteners. However, the adjacent edged panels of the mattress are permanently laced together for secure assembly.

When it comes to assembly, the welded mesh structure is easy to assemble using spiral coils with a 20mm internal diameter and a pitch of 45mm, as previously mentioned. These spiral coils serve as fasteners, simplifying the process. Alternatively, hog rings can also be utilized either in conjunction with or independently of the spiral coils. However, the hexagonal double twisted wire requires lacing wire of 2mm diameter to lace the mesh structure, which is a more time-consuming method and adds to labor costs.

Finish coating

At Hitech Gabion, customer satisfaction is our priority, and we offer a variety of finish coatings to meet your needs. By default, we provide a hot dip galvanized finish coating on our materials, adhering to BS EN 1461 or equivalent standards for both categories of Reno mattresses. Additionally, upon request, we offer PVC coating with custom colors, ensuring you have options to suit your specific requirements.

Shape control and Bending

To maintain the shape of Reno mattresses and prevent deformation, diaphragm panels are installed in both categories. These panels offer strength, ensuring the mesh structure remains intact under stress. Additionally, we suggest incorporating supporting wires with a diameter of 2mm during installation to enhance stability further. Compared to twisted woven wires, the welded mesh structure offers superior shape control, providing added assurance against shape alteration over time.